Introduction

Hoffman kiln is a continuous, moving fire kiln in which the fire is always burning and moving forward through the bricks stacked in the circular, elliptical or rectangular shaped closed circuit with arched roof. The fire movement is caused by the draught provided by a chimney or a fan.

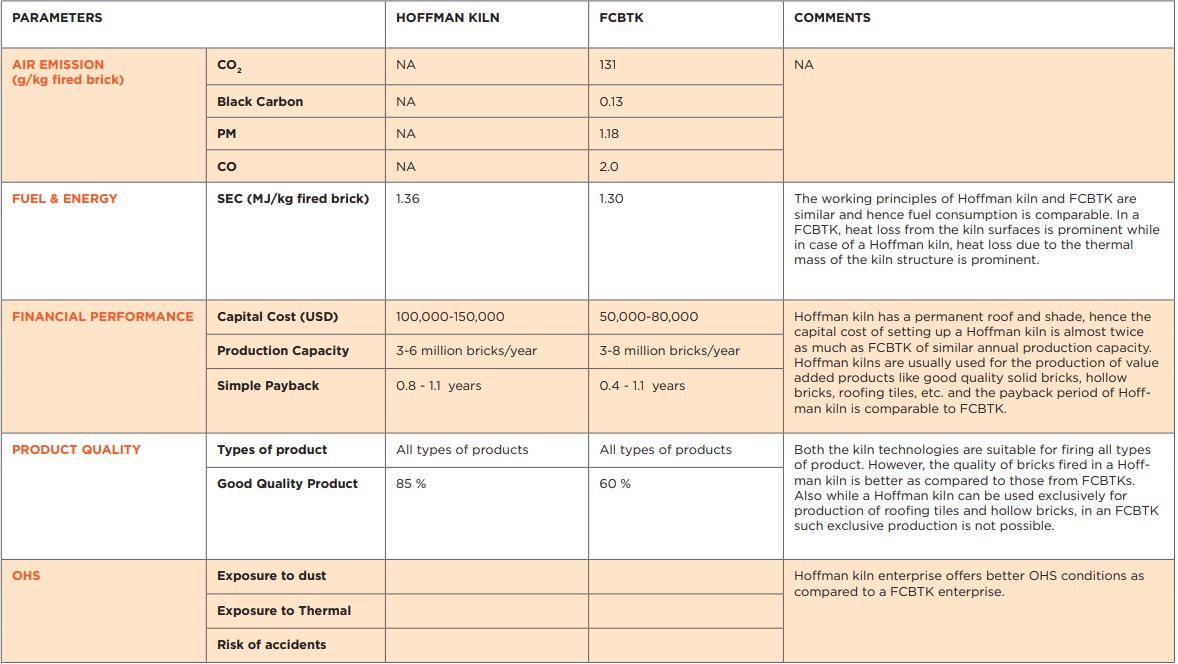

The Hoffman kiln has a production capacity of 10,000 to 20,000 bricks per day and requires 15-20 operators. The payback period for this kiln is 0.8-1.1 years for simple payback and 0.9-1.2 years for discounted payback. The product quality is perceived as under-fired and over-burnt. The specific energy consumption for firing 1 kg of fired brick is an average of 1.36 MJ/kg.

The financial performance shows that the capital cost for the Hoffman kiln is higher than the FCBTK, but the production capacity and payback period are comparable.

The product quality of the Hoffman kiln is better compared to FCBTK, and it offers better occupational health and safety conditions.

Performance of Hoffman kiln is compared with the most commonly used continuous kiln technology in the region which is FCBTK.